Aviation Needs Dehumidification: a match made in heaven (or the sky)

May 18, 2020

Believe it or not, relative humidity (RH) is a big issue for the aviation sector both in the sky and on the ground, which means aviation needs dehumidification. This article explores the potential problems associated with RH and aircraft and looks at what solutions can stop the issue at its source.

Have you ever wondered how planes form vapour trails in the sky? It may seem a tepid 22-24 degrees with a dehydrating 12% RH inside (drier than most deserts). However, research shows that outside the body of the craft, temperatures plummet. If the ground-level temperature sits at 20 degrees celsius, at 35,000 feet, the air temperature would be around -54 degrees.

Because cold air harbours gaseous water, when it comes into contact with the cold metal fuselage at 30,000 feet high, the gaseous water gathers quickly condenses and cools, forming droplets and leaving trails in the sky.

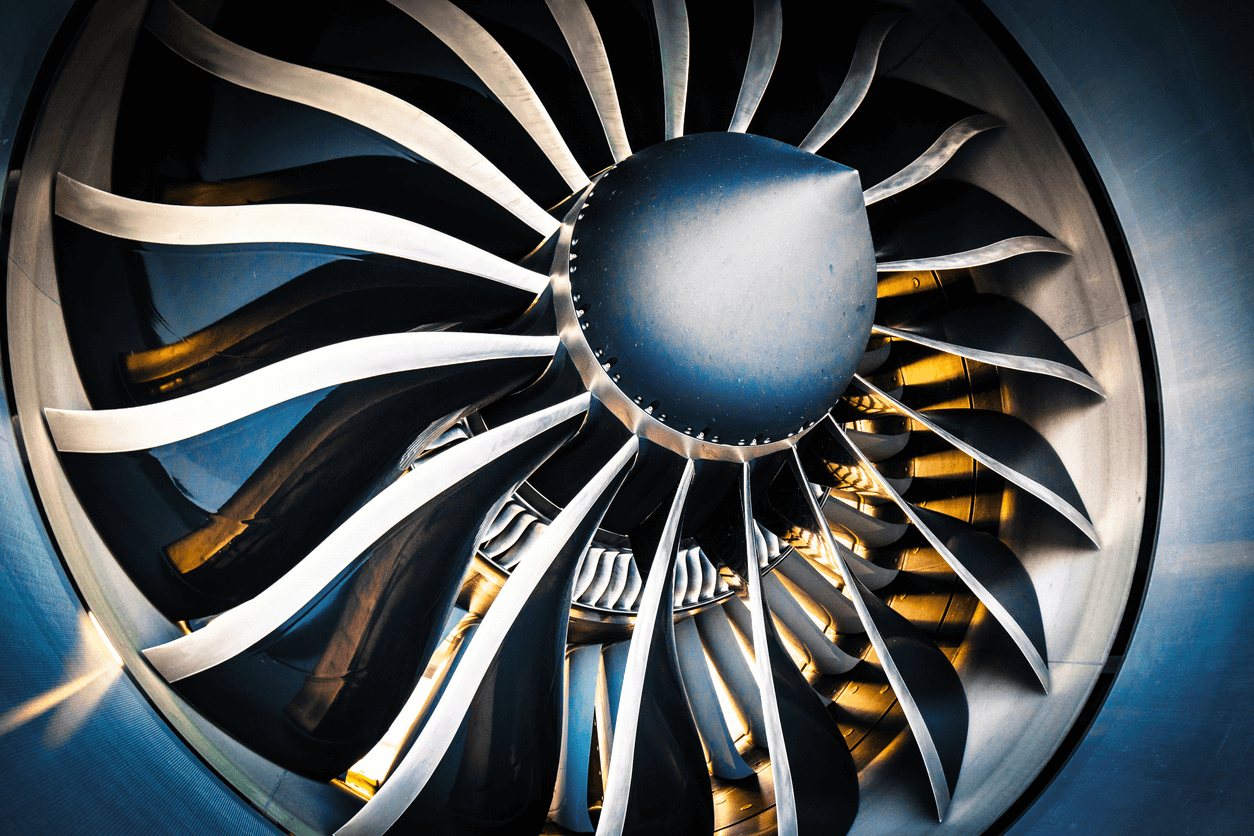

So what does this tell us? It demonstrates just how planes pick up so much moisture while in the air, which decreases the performance because of the effect on the engine as well as the wings, caused by the drop in external temperature and the rise of the internal temperature. The moisture is trapped in the aircraft and has to be released upon landing to maintain its efficiency and functionality.

This does two things;

1- Burns extra fuel. It takes more fuel to transport more weight. By removing the extra weight, less fuel is used, and money is saved.

2- Increases ground time. The only time to get the extra water weight out of the aircraft is when it is on the ground. A grounded plane can’t transport passengers, and therefore your efficiency is compromised, and money is lost during the plane’s ground time.

What about the safety of the aircraft?

Avionics are the electronic systems used on an aircraft. There are lots of these small, precise electronic workings in planes that should be kept in optimal conditions.

Moisture doesn’t react well with electricity, so if something were to happen with an internal moisture build-up, there could be potentially dangerous repercussions. The aviation relies on effective dehumidification to remove any worry of this and to keep everything in its ideal condition.

Dehumidification on the ground

Not only are the effects of RH felt in the air; transporting and storing aircraft on the ground is going to raise a few issues. It used to be the case that aircraft manufacturers would apply a layer of coating to parts to prevent humidity damage during transportation. Now, environmental legislation stops this from happening, which is just as well since the process of repeatedly coating parts is labour intensive and costly. It’s also not the best solution out there by far.

What’s the best solution for transporting aircraft?

A transportation system that’s tailored to your requirements is usually the most appropriate solution.

A system that maintains a controlled and conditioned environment on a moving vehicle that’s over 30 meters long will ensure your parts are protected from damage.

With this system, temperature and humidity are simultaneously controlled to specific set points, while being easily powered on a moving vehicle.

The latest controls function for this system is developed by us, including data logging, ethernet connections, wireless connection and an App to track the conditions throughout the transportation cycle, enabling complete traceability for the life of the components.

Conclusion

Overall, aviation needs dehumidification in overcoming a number of challenges, whether that’s among the clouds in the sky or on the ground.

A dehumidification system for both transporting your craft and keeping it safe and efficient in the skies is the best solution out there, taking away the laborious tasks of removing water when the plane is on the ground or coating individual parts for transport.

If you have any questions or want to enquire, get in touch today.

For over twenty-one years, Dehum (Sorption Wheel Services Limited) has been a major supplier of humidity control systems. We are a true Engineering Company, designing, supplying and coordinating installations of equipment alongside complimentary services. Our global client list spans across all industries, including food & drink, pharmaceutical, nuclear, automotive, aviation, chemical processing, ice prevention/cold storage, car storage and archives.